Steam Shower Buyers Guide

After supplying steam showers for over 11 years, Maya Bath considers itself one of the steam shower experts within the industry. Maya Bath understands the importance of making the correct buying decision when deciding on a new steam shower. With an abundance of models available in the marketplace, it’s important to know what to look for and certain things you should avoid.

Let Maya Bath make the notes for you! The following is essential advice to read and check before you buy your new steam shower. Steam shower prices vary massively both online and on the high street, but it’s important not to just settle for the cheapest unit available.

The following guide is designed to give you an insight into some of the factors you need to be aware of when shopping for your new steam shower. If you have any questions for our experts, don’t hesitate to drop us an email through our contact page.

Acrylic Quality & Finish

Aluminium Framing And Columns

Tempered Safety Glass

Sealant, Water Flow & Pipework

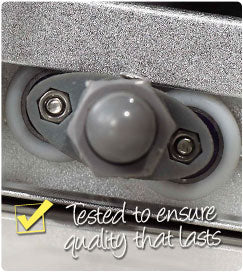

Product Testing & Durability

Electrics & Safety

Installation & Delivery

Warranty & After Sales

Design & Features

Online Security

Company background